PU Coating Waterproofing Solution

PU coating is a liquid waterproof layer that dries into a strong, flexible “protective skin” over your surface. It sticks well to concrete, metal, tiles, and roofs, and has no joints where water can sneak in.

It can handle Malaysia’s hot sun, heavy rain, and small cracks without breaking. When applied properly, it helps stop leaks, protects the surface, and lasts for many years with minimal maintenance.

What is PU Coating

PU Coating (also known as Polyurethane Coating) is a high-performance, liquid-applied waterproofing system designed to create a seamless and fully bonded protective membrane over exposed surfaces. Applied as a liquid, the coating cures into an elastic, durable film that adheres strongly to concrete, screed, metal, tiles, and various roofing substrates, forming a continuous waterproof layer with no joints or weak points.

Our PU coatings are made from premium-grade polyurethane with excellent flexibility, tensile strength, and UV resistance. This advanced formulation allows the coating to accommodate structural movement, bridge hairline cracks, and withstand long-term exposure to heat, sunlight, and ponding water. Its ability to expand and contract without breaking makes it especially suitable for Malaysia’s hot and humid climate.

PU coating provides a robust barrier against water ingress, weathering, and surface deterioration. When paired with expert surface preparation and precise application, PU coating delivers a long-lasting waterproofing solution that enhances the lifespan of exterior surfaces while reducing maintenance needs.

Key Benefits of PU Coating

Our PU coating system provides excellent flexibility, UV resistance, and strong adhesion, forming a seamless waterproof layer that stands up to heat, weathering, and surface movement. It is ideal for both commercial and residential projects that require reliable, low-maintenance protection for exposed areas.

Efficiency

PU coating offers a fast and efficient installation process, reducing downtime and allowing waterproofing works to be completed with minimal disruption, ideal for both commercial and residential properties.

Resistant

Highly flexible and UV-stable, the coating withstands thermal movement, direct sunlight, and ponding water, maintaining consistent waterproofing performance over time.

Versatility

Adapts well to complex details, uneven surfaces, & roof penetrations. Its liquid-applied system, it provides seamless coverage even around difficult areas.

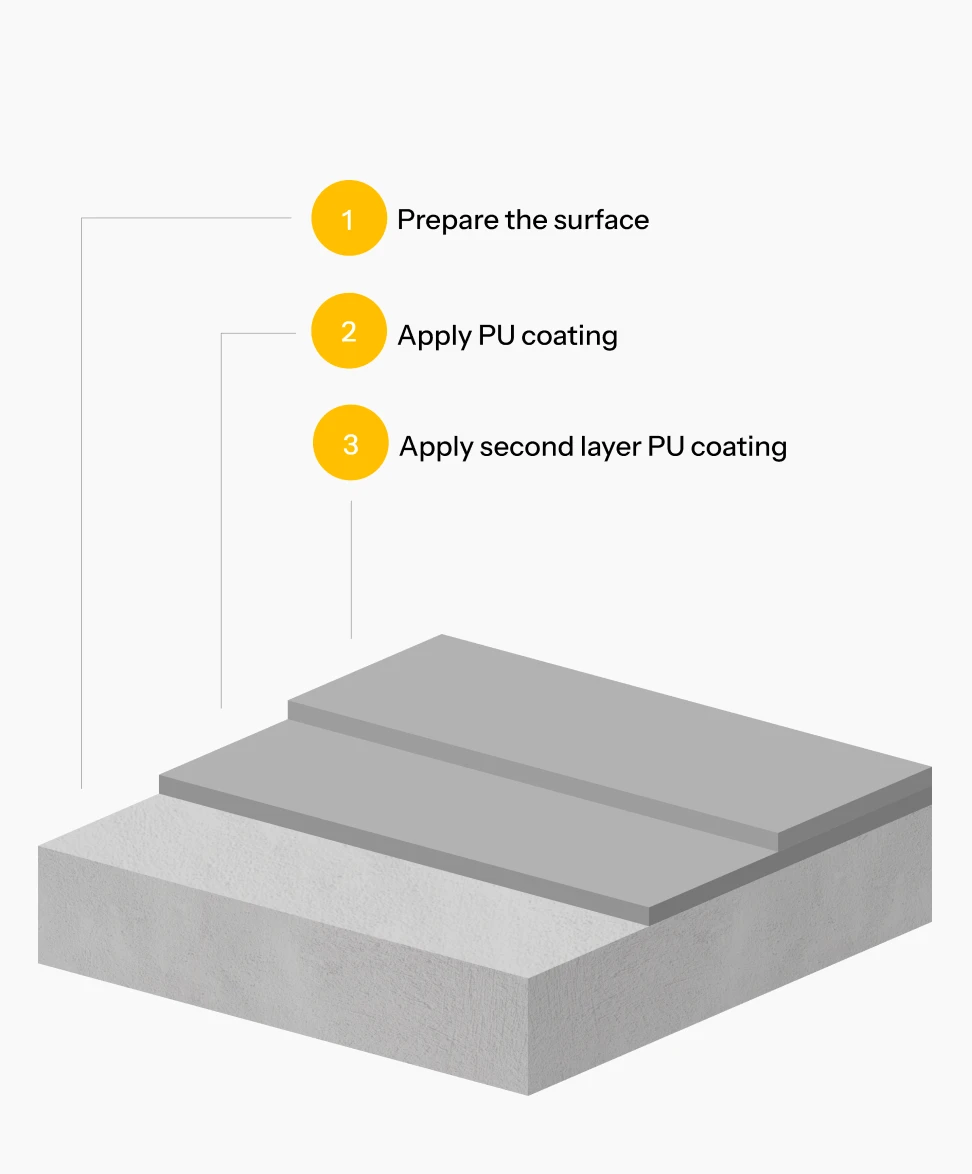

PU Coating Application Method

Let’s take a step-by-step deep dive into how a PU Injection waterproofing system is applied, breaking down each stage from surface preparation to the final injection process, with clear steps, technical details, and practical considerations.

-

1

First Layer: Prepare the surface

Clean, dry, and lightly sand the area to remove dust, dirt, grease, and loose material. Repair any major cracks or holes first -

2

Second Layer: Apply the Coating

Choose a brush, roller, or spray, and spread thin, even coats, making sure edges and corners are fully covered. -

3

Third Layer: Repeat for Full Coverage

Allow the first coat to dry, lightly sand if needed, then apply a second coat perpendicular to the first for complete protection.

Our Past Projects

From hotels and government facilities to major engineering ventures and upscale residences, ARCHTECH Waterproofing is trusted nationwide. We deliver solutions built for long-term durability, supported by the technical expertise needed at every step of the project.

Explore Our Comprehensive Range of Waterproofing Method

Need Waterproofing Help?

Tell us what you’re facing, whether it’s a leak, damp smell, mould stain or bubbling paint. You can also upload a photo for faster assessment. Our team will review your case and get back to you with a personalised solution and quotation.